Frabes produce nei suoi stabilimenti a Rovato in Italia materie prime lattiero casearie destinate ad essere commercializzate e utilizzate nella formulazione dei sostitutivi del latte. La nostra produzione di materie prime è strettamente collegata al nostro territorio, la Pianura Padana, in cui si trovano gli allevamenti che forniscono il latte per la produzione di formaggio Grana Padano e Parmigiano Reggiano e gran parte del siero liquido che ne risulta viene da noi lavorato.

La produzione di Grana Padano inizia con il latte crudo da vacche munte due volte al giorno e che deve essere raccolto entro ventiquattro ore dalla prima mungitura. L’alimentazione delle vacche stesse è rigorosamente controllata e deve rispettare il Disciplinare di Produzione mantenendo così alti gli standard qualitativi del latte e del formaggio stesso.

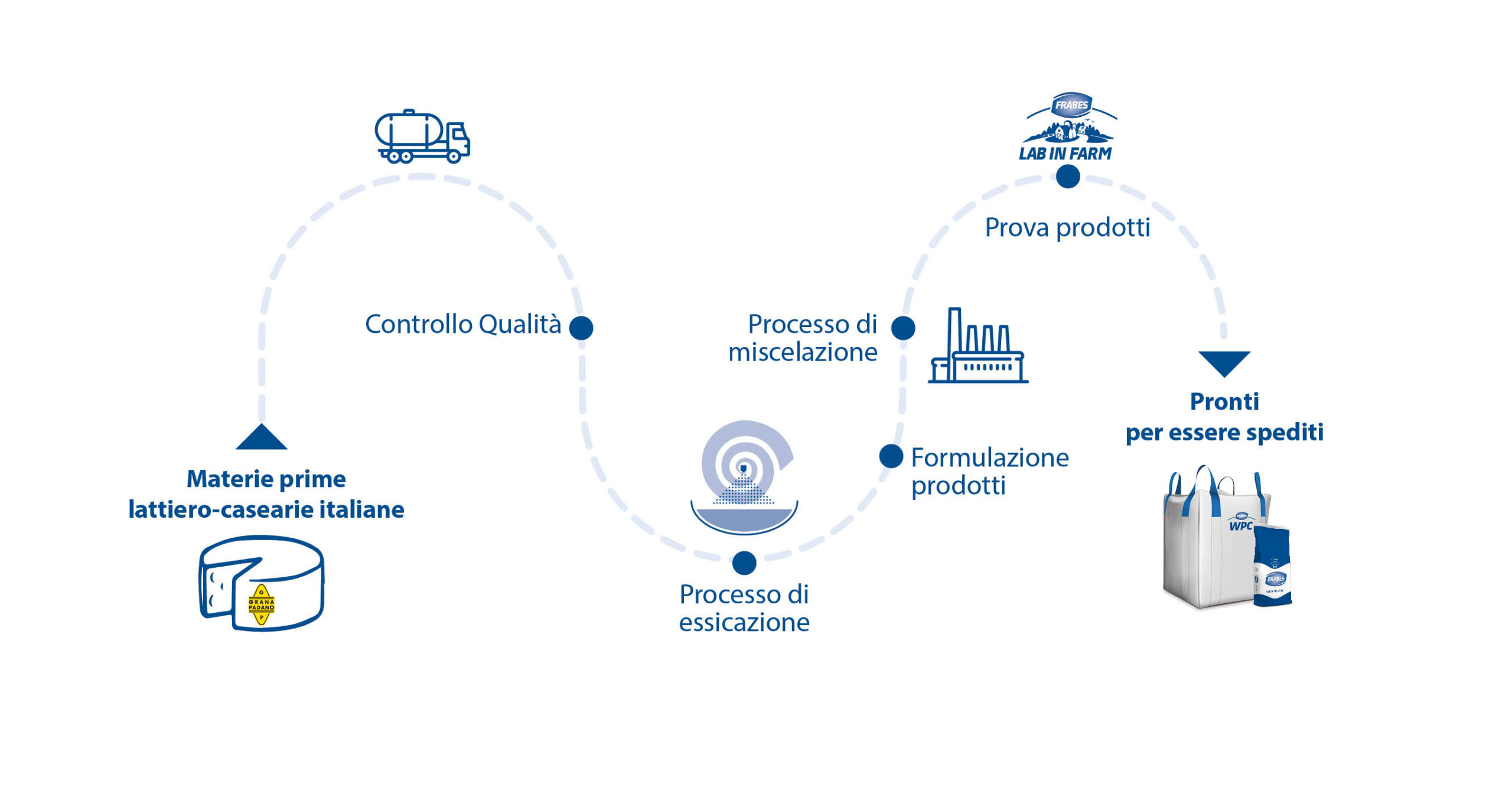

Dal caseificio alla trasformazione, il latte non può essere sottoposto a trattamenti fisici, meccanici o termici che possono alterare il suo stato di latte naturale non trattato. Il latte viene quindi posto in caldaie a campana rovesciata (vasche), in rame o con un rivestimento interno in rame. La coagulazione si ottiene utilizzando il caglio di vitello, dopo l’aggiunta di un iniziatore naturale di siero di latte. Quello che otteniamo, dopo aver lavorato circa 1000 litri di latte, sono 80 kg di formaggio Grana Padano fresco e 900 litri di siero liquido; il siero liquido dopo un lungo processo, arriva quindi in Frabes per iniziare la produzione di WPC (concentrato proteico di siero di latte).

Il WPC è quindi pronto per poter essere venduto e spedito oppure trasferito nel nostro impianto per la produzione di sostituti del latte.